Metal can warp when perforated due to several factors related to the perforation process and the properties of the metal itself:

The perforation process involves applying force to the metal sheet to create holes. This can induce stress and strain in the metal, especially around the edges of the perforations. If the force applied during perforation is not evenly distributed or if the metal is not adequately supported during the process, it can lead to warping or distortion of the sheet.

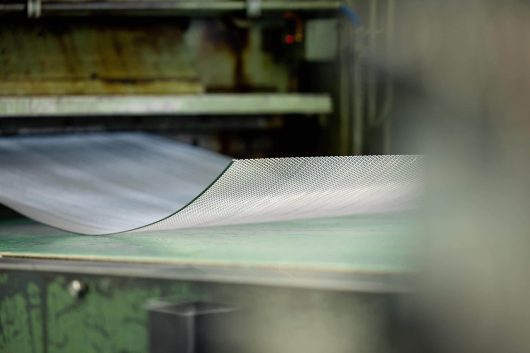

To reduce any distortion, the material is guided and aligned in the CNC levelling rolls. These rolls exert controlled pressure on the material as it passes through, gradually flattening and straightening it. The number and configuration of the rolls may vary dependant on the type, thickness and width of the material.

Levelling perforated sheets is essential for ensuring the material meets the dimensional tolerances and surface quality required for further processing or use in many applications.

Levelling will ensure the perforated sheet is uniformly flat, it will enhance the aesthetic appearance by removing distortion providing a smoother looking sheet, especially important in architectural and interior applications. It ensures that perforated metal sheets maintain their intended functionality. In applications such as filtration, screening, or ventilation, where precise hole size, shape, and distribution are critical, a level surface ensures optimal performance and efficiency.